- This topic is empty.

-

AuthorPosts

-

2025-09-26 at 10:48 am #10529

Superior Stability Single Crystal Silicon Differential Pressure Transmitter Shines

You experience unmatched stability and reliability with the single crystal silicon differential pressure transmitter. Advanced features, such as high precision and temperature compensation, set this device apart. Technical research highlights its ability to measure temperature and pressure precisely. AOSHENG’s single crystal silicon differential pressure trans reflects true product innovation for your industry needs.

Key Takeaways

-

The single crystal silicon differential pressure transmitter offers high accuracy with typical values reaching ±0.075% FS, ensuring reliable measurements over time.

-

Built-in temperature compensation minimizes drift, keeping measurements stable even with temperature changes, which enhances process control.

-

Aosheng's transmitter features robust design and low maintenance needs, making it a cost-effective choice for long-term industrial applications.

Single Crystal Silicon Differential Pressure Transmitter

Sensor Technology

You benefit from advanced sensor technology when you choose the single crystal silicon differential pressure transmitter. This device uses a core sensor made from single crystal silicon. The unique structure of this material gives you excellent stability and long-term reliability. You can trust the transmitter to deliver accurate readings, even in harsh industrial environments.

Aosheng’s transmitter stands out because of its high precision and strong anti-interference ability. You also get the advantage of modern digital communication protocols. These features make installation and maintenance much easier for you. The table below highlights some of the key features that set this transmitter apart:

Feature

Description

Anti-Interference

The core sensor made from single crystal silicon offers excellent stability and anti-interference ability.

Digital Communication Protocols

Supports various protocols including HART, PROFIBUS PA, and FF, enabling remote calibration and diagnosis.

You can see how these features help you achieve reliable and efficient process control.

Measurement Principle

The single crystal silicon differential pressure transmitter uses a measurement principle based on the piezoresistive effect. Here is how it works:

-

The sensor detects pressure by measuring changes in resistance caused by deformation of the silicon lattice.

-

This method gives you high precision and stability, with typical accuracy reaching ±0.075% FS.

-

The use of single crystal silicon ensures excellent stability, anti-interference, and long-term reliability.

-

You can apply this technology in many industrial settings, such as petrochemical plants, power stations, and water treatment facilities.

You gain confidence in your measurements because the transmitter maintains accuracy and performance over time.

Stability Advantages

Long-Term Accuracy

You demand precision in every measurement. The single crystal silicon differential pressure transmitter delivers consistent accuracy over time. You see a typical accuracy of ±0.075% FS, which means you can trust your readings even after years of operation. The sensor resists drift, so you do not need to worry about frequent recalibration. You maintain control over your process with confidence. The transmitter’s advanced design ensures that your data stays reliable, supporting your decision-making in critical environments.

Tip: Regular calibration checks help you maintain peak performance, but with this transmitter, you spend less time on maintenance.

Temperature Compensation

You often face changing temperatures in industrial settings. The single crystal silicon differential pressure transmitter uses a built-in temperature compensation algorithm. This feature keeps your measurements stable, even when the temperature shifts. You experience minimal temperature drift, as low as ±0.15% for every 10℃ change. This stability means you do not lose accuracy during seasonal changes or sudden temperature spikes. You keep your process running smoothly, no matter the climate inside your facility.

Reliability

You rely on your equipment to perform under tough conditions. The single crystal silicon differential pressure transmitter stands up to harsh environments. You benefit from overload protection, which allows the transmitter to handle up to 40 times its rated range. You see long-term drift limited to ±0.1% FS per year, so your readings stay consistent. The transmitter maintains stability at ±0.1% FS over three years, giving you peace of mind for long-term projects.

Comparison with Other Transmitters

Thin-Film and Capacitive Types

You often see thin-film and capacitive sensors in industrial settings. Thin-film sensors use a metal film on a substrate to detect pressure changes. Capacitive sensors measure pressure by detecting changes in electrical capacitance between two plates. These technologies have served many industries for years. However, you may notice that they can struggle with long-term stability and accuracy, especially in harsh environments. You might also find that they require more frequent calibration to maintain performance.

Performance Differences

When you compare these traditional sensors to the single crystal silicon differential pressure transmitter, you see clear advantages. You get higher accuracy, with typical values reaching ±0.075% FS. You also benefit from excellent temperature compensation, which keeps your readings stable even when temperatures change. Maintenance becomes easier for you because the transmitter resists drift and needs fewer adjustments over time.

Here is a quick comparison:

Feature

Thin-Film/Capacitive Sensors

Single Crystal Silicon Differential Pressure Transmitter

Accuracy

Moderate

High

Stability

Can drift over time

Excellent long-term stability

Temperature Influence

Higher drift

Minimal drift

Maintenance

Frequent calibration needed

Low maintenance

Note: You improve process reliability and reduce downtime when you choose advanced sensor technology.

Real-World Applications

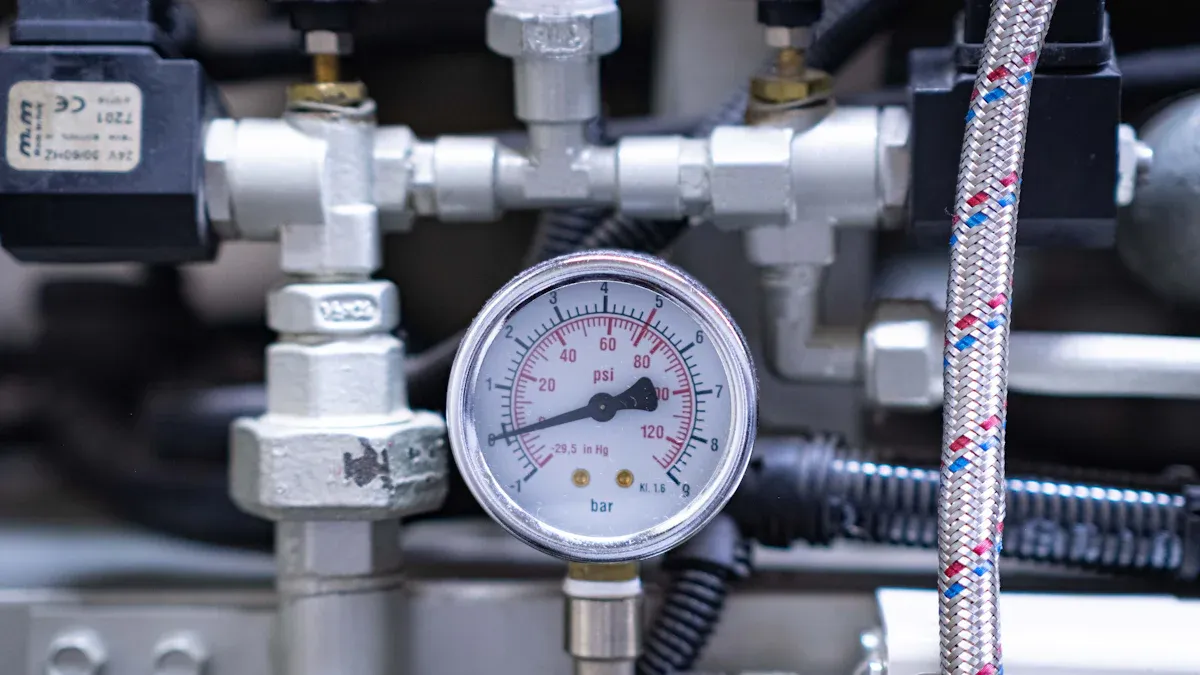

Image Source: unsplash Industrial Use Cases

You see the single crystal silicon differential pressure transmitter used in many industries. In petrochemical plants, you monitor reactor liquid levels and control process flows. Electric power facilities rely on this transmitter to measure steam pressure and ensure safe turbine operation. Pharmaceutical companies use it to maintain clean environments and regulate pressure in production lines. Water treatment plants depend on accurate pressure readings to manage filtration and distribution systems. You benefit from precise measurements and stable performance in each of these settings.

Tip: You improve safety and efficiency when you choose advanced pressure transmitters for critical applications.

Cost and Lifecycle

You want equipment that saves money and lasts a long time. The single crystal silicon differential pressure transmitter offers cost-effective operation because it needs less maintenance and calibration. You reduce downtime and avoid frequent replacements. The transmitter’s robust design supports a long lifecycle, even in harsh environments. Explosion-proof certification lets you use it safely in hazardous areas. You protect your investment and ensure reliable process control.

Aosheng stands out as a trusted partner. You get products built with advanced technology and high stability. The company’s commitment to quality and rich experience in sensor development give you confidence in every purchase.

Evidence Description

Details

Commitment to Quality

Aosheng emphasizes 'quality first' and 'reputation as the priority'.

Experience in the Field

Rich experience in high-precision sensors and instruments.

Advanced Technology

Uses advanced single crystal silicon differential pressure transmitters.

High Stability Products

Provides excellent quality products with high stability.

You rely on Aosheng for reliable solutions that support your process control needs.

You gain superior stability and reliability with single crystal silicon differential pressure transmitters.

-

You benefit from high accuracy, minimal drift, and robust design.

-

You trust Aosheng’s dedication to quality and innovation.

Choose Aosheng for dependable process control solutions in your industry.

FAQ

How do you install the single crystal silicon differential pressure transmitter?

You mount the transmitter securely, connect the process lines, and wire the electrical connections. Always follow the manufacturer’s instructions for best results.

What maintenance does this transmitter require?

You check for leaks, inspect wiring, and perform periodic calibration.

-

Regular visual inspections help you catch issues early.

Can you use this transmitter in hazardous environments?

Yes, you can. The transmitter has explosion-proof certification, so you use it safely in hazardous areas like chemical plants or refineries.

http://www.aoshengat.com

AOSHENG Automation Technology Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.