- This topic is empty.

-

AuthorPosts

-

2026-02-09 at 11:40 am #11408

Copper foil is a critical component in the production of lithium-ion batteries, serving as the anode current collector. The performance, thickness uniformity, and surface quality of copper foil directly influence battery efficiency, energy density, and safety. As electric vehicles, portable electronics, and renewable energy storage systems continue to expand, the demand for high-quality copper foil has surged.

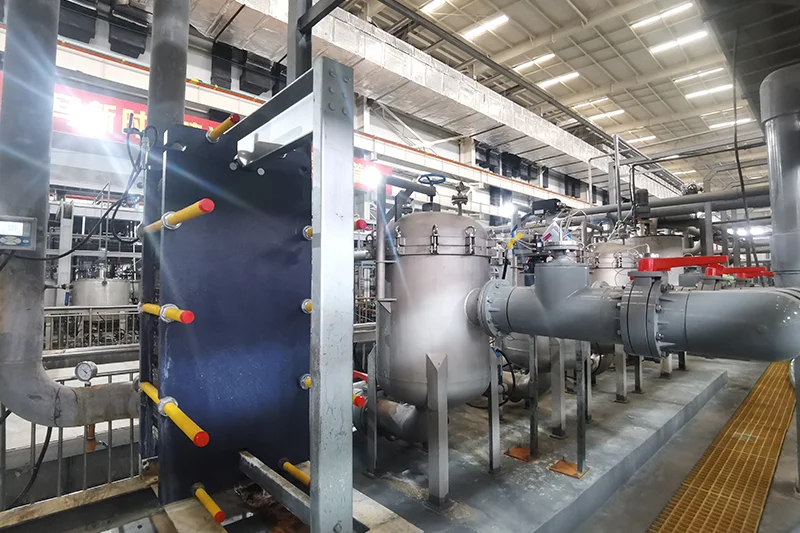

Timonic specializes in advanced copper foil production equipment, providing solutions for the precise and consistent manufacturing of battery-grade copper foils. In this article, we explore the key machine features, production solutions, and industry trends that enable high-performance lithium battery applications.

The Role of Copper Foil in Lithium Batteries

In a lithium-ion battery, copper foil serves as the current collector for the anode, connecting the active material to the battery terminal. Key requirements for copper foil include:

-

High electrical conductivity to ensure efficient current flow

-

Uniform thickness to maintain consistent energy density

-

Smooth and defect-free surface for reliable electrode coating adhesion

-

Mechanical strength to withstand rolling, cutting, and battery assembly

Meeting these requirements necessitates precision machinery and strict process control throughout the copper foil production line.

Key Features of Modern Copper Foil Production Machines

Modern battery-grade copper foil machines are designed to deliver ultra-thin, uniform, and high-strength foils with minimal defects. Timonic’s production equipment incorporates several advanced features:

1. Continuous Casting and Rolling Integration

-

Seamless transition from molten copper casting to rolling

-

Ensures uniform thickness and metallurgical consistency

-

Reduces oxidation and surface irregularities

2. Precision Rolling Systems

-

High-accuracy roll gap control

-

Multi-stage rolling with adjustable tension

-

Ability to produce foils with micron-level thickness precision

3. Surface Treatment Units

-

Electrolytic or chemical treatments to enhance adhesion

-

Controlled roughening for improved electrode coating

-

Consistent surface texture across wide rolls

4. Automated Tension and Speed Control

-

Synchronized motor drives to minimize foil stretching

-

High-speed production without compromising quality

-

Real-time thickness monitoring with feedback control

5. Advanced Coating and Slitting Solutions

-

Integration of protective coatings when required

-

Precision slitting for battery-grade widths

-

Minimal edge defects for safe electrode assembly

Production Solutions for Battery Manufacturers

Timonic’s copper foil machines are designed to support high-volume lithium-ion battery production while maintaining consistent quality:

-

Thin Foil Production: Capable of producing foils as thin as 4–12 μm for high-energy-density batteries

-

Wide Foil Options: Machines support widths up to 2,000 mm, suitable for large-format cells

-

High Mechanical Strength: Advanced rolling and annealing processes enhance tensile strength, minimizing breakage during coating and winding

-

Customizable Process Parameters: Operators can adjust speed, tension, and surface roughness to match specific electrode requirements

These solutions are particularly suited for applications in electric vehicles, energy storage systems, and portable electronics.

Benefits of Advanced Copper Foil Machines

-

Improved battery performance due to high-quality foils

-

Reduced material waste through precise thickness control

-

Enhanced process efficiency with continuous and automated production

-

Lower defect rates for safer, more reliable lithium-ion cells

-

Flexibility to adapt to different foil thicknesses and surface treatments

Frequently Asked Questions (FAQ)

1. What thickness of copper foil is typically used in lithium-ion batteries?

Battery-grade foils typically range from 4 μm to 12 μm for high-energy-density applications, but thickness can vary depending on battery design and cell format.

2. How does foil uniformity affect battery performance?

Non-uniform thickness can lead to uneven current distribution, lower energy density, and localized heating, reducing overall battery efficiency and lifespan.

3. Why is surface roughness important for copper foils?

Controlled roughness improves adhesion of the electrode coating while maintaining low electrical resistance. Too rough or too smooth a surface can impact coating quality.

4. Can Timonic machines produce wide foils for large-format battery cells?

Yes, Timonic’s equipment supports foil widths up to 2,000 mm, suitable for electric vehicle and energy storage battery manufacturing.

5. Who manufactures these high-quality copper foil machines?

The machines are produced by Timonic, a leading provider of battery-grade copper foil equipment, offering complete solutions for precision, efficiency, and reliability.

Timonic Company BackgroundConclusion: High-Performance Copper Foil Production for Modern Batteries

Producing high-quality copper foil is essential for modern lithium-ion battery performance. Timonic’s advanced machinery provides manufacturers with the precision, efficiency, and flexibility required for high-volume production while meeting the stringent quality standards of today’s energy storage applications.

By integrating continuous casting, precision rolling, surface treatment, and automated controls, Timonic machines help battery producers achieve consistent, defect-free copper foils that directly contribute to higher energy density, safety, and reliability in lithium-ion cells.

For battery manufacturers looking to optimize production and quality, Timonic’s copper foil solutions represent a strategic investment in next-generation energy technology.

How EPC Services Streamline New Copper Foil Plant Construction and Deployment

http://www.timonic.com.cn

Timonic (Suzhou) Technology Co., Ltd -

-

AuthorPosts

- You must be logged in to reply to this topic.