- This topic is empty.

-

AuthorPosts

-

2025-06-20 at 4:46 pm #9851

https://www.boqini-heatrecovery.com/High-Temperature-Flue-Gas-Heat-Exchanger-Recover-Energy.html

Harnessing Heat from Waste: The Role of Flue Gas Heat Exchangers

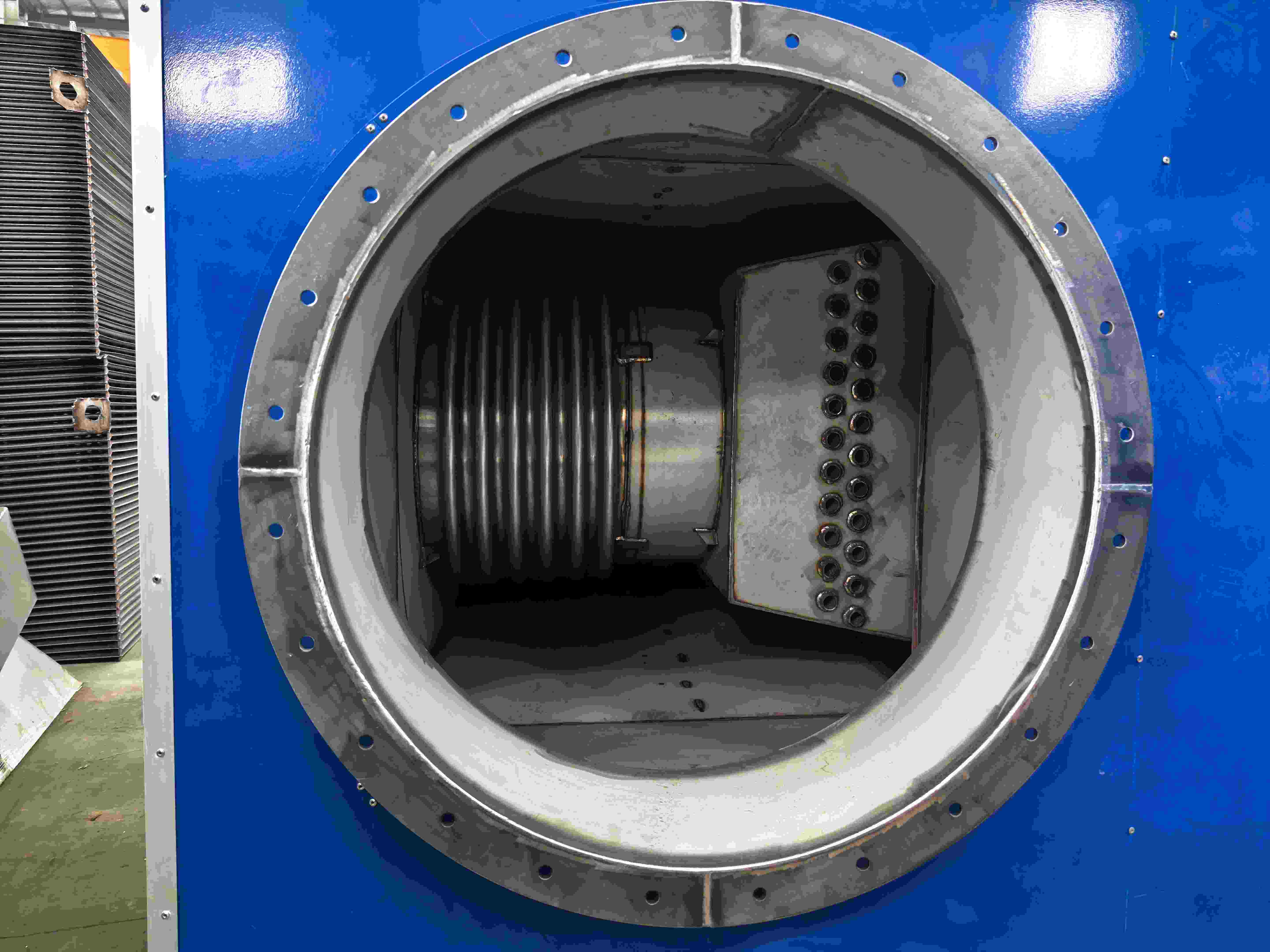

In modern waste management, waste incineration is not just about reducing landfill volume — it is also a significant source of renewable energy. Central to this energy recovery process is the high temperature flue gas heat exchanger, a critical technology that captures the thermal energy from flue gases emitted at the tail end of incinerators.

At Jiangsu Boqini Environmental Protection Technology Co., Ltd., we specialize in designing and manufacturing advanced heat exchanger systems tailored for the harsh conditions of waste incineration facilities. Our solutions are engineered to recover maximum heat energy efficiently, turning potential waste into valuable power or heat for industrial and municipal applications.

Advanced Thermal Recovery from Incineration Processes

During waste incineration, the combustion process generates extremely hot flue gases—often exceeding several hundred degrees Celsius. Without proper recovery, this energy escapes into the atmosphere, representing both a loss of potential utility and an environmental concern.

Our high temperature flue gas heat exchanger is specifically developed to extract thermal energy from these gases before they are released. By transferring this heat to a working fluid, such as water or thermal oil, the system enables the production of steam for electricity generation or provides heat for district heating networks, manufacturing processes, or pre-drying systems.

Engineering for Extreme Conditions

Flue gas from incinerators contains not only high heat but also corrosive substances like sulfur oxides, chlorine compounds, and fine particulates. To handle these challenges, Jiangsu Boqini employs robust materials and advanced engineering strategies:

-

Corrosion-resistant alloys and protective coatings extend the lifespan of components.

-

Modular design allows for easy maintenance and adaptability to different flue gas compositions.

-

Thermal stress management ensures stability under rapid temperature fluctuations.

Every unit is designed with safety, durability, and performance in mind, allowing for continuous operation even in the most demanding environments.

Sustainable Energy Generation and Emission Reduction

The use of high temperature flue gas heat exchangers in waste incineration aligns with global efforts to reduce fossil fuel dependence and lower carbon emissions. By recovering heat from waste combustion, we contribute to a circular energy economy where waste is transformed into a renewable resource.

This technology supports combined heat and power (CHP) systems, enhancing the overall efficiency of waste-to-energy plants. The reduced reliance on conventional fuels results in lower operational costs and a smaller environmental footprint.

Jiangsu Boqini’s Commitment to Clean Energy Innovation

As a leading developer of flue gas treatment and energy recovery solutions, Jiangsu Boqini Environmental Protection Technology Co., Ltd. brings innovation, precision, and environmental responsibility to every project. Our experience in waste incineration systems has enabled us to create highly efficient and customized heat exchangers for municipal and industrial clients.

From the initial consultation to the final system integration, we deliver solutions that meet the unique demands of each facility. Our focus on high-performance equipment, backed by rigorous testing and ongoing support, ensures that clients can depend on long-term reliability and optimal thermal recovery.

Turning Waste Heat into Valuable Energy

The high temperature flue gas heat exchanger is a transformative technology in the field of waste incineration. By capturing and reusing heat that would otherwise be lost, it turns incineration plants into powerful energy hubs.

At Jiangsu Boqini Environmental Protection Technology Co., Ltd., we are proud to be at the forefront of this advancement. Our heat exchangers not only improve plant efficiency but also support global goals for energy sustainability and environmental protection.

https://www.boqini-heatrecovery.com/Waste-Incineration-Furnace-Manufacturer-Lithium-Battery.html

https://www.boqini-heatrecovery.com/High-Temperature-Flue-Gas-Heat-Exchanger-Recover-Energy.html

Jiangsu Boqini Environmental Protection Technology Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.