- This topic is empty.

-

AuthorPosts

-

2025-06-16 at 11:50 am #9787

Under the general trend of intelligent manufacturing, the home appliance manufacturing industry is undergoing an important transformation from "automation" to "flexibility". In particular, facing the market demand for multiple varieties, small batches and fast delivery, traditional rigid assembly lines can no longer meet the high efficiency and flexibility requirements of modern home appliance production. As a highly modular, scalable and intelligently controlled advanced manufacturing model, flexible assembly lines are gradually occupying an important position in the field of home appliance manufacturing. This article will systematically analyze the application value, actual scenarios, key technologies of flexible assembly lines in the home appliance industry, and how to choose suitable flexible assembly line manufacturers and solutions.

1. Industry pain points and challenges of home appliance manufacturing

In recent years, the home appliance industry has shown the following major development trends:

Consumption upgrades have brought about product customization needs: consumers are increasingly preferring personalized, intelligent and multifunctional home appliances;

New product iteration speed is accelerated: the frequency of brand renewal is increasing, and traditional production lines are difficult to adapt to rapid switching;

There are many categories and unstable batches: a production line may need to take into account multiple models of products at the same time;

Labor costs are rising and labor turnover is large: traditional production lines that rely on manual operations are inefficient and unstable.

These changes have directly promoted the penetration of flexible manufacturing technology in the home appliance industry, and flexible assembly lines are the core technical means to solve the above problems.

2. What is a flexible assembly line?

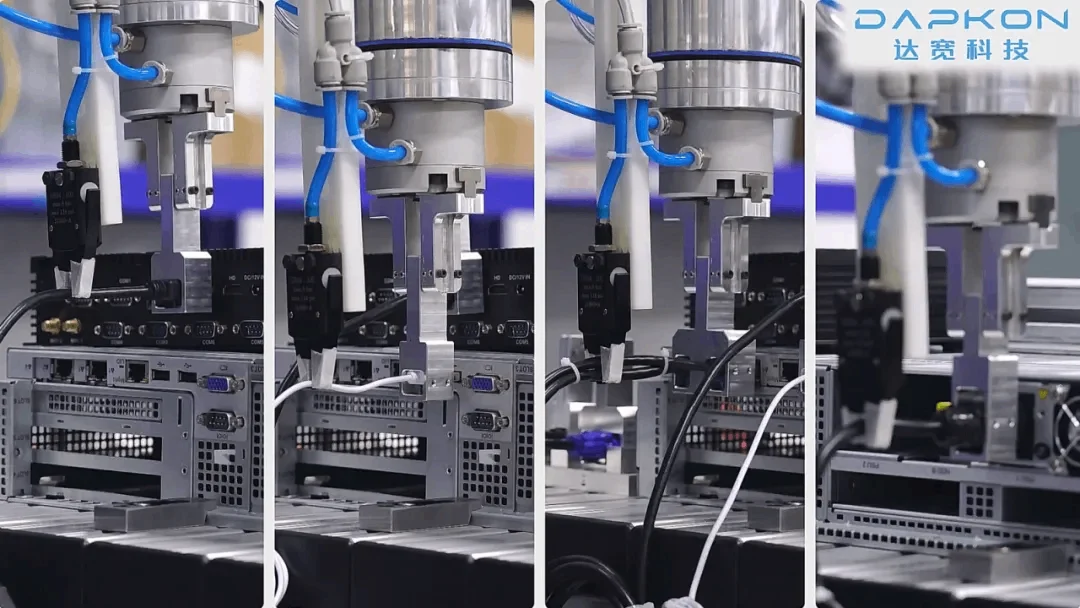

A flexible assembly line refers to an assembly system that realizes flexible scheduling of assembly processes and rapid switching of multiple products through means such as programmable control systems, automation modules, industrial robots, and AGV automatic handling equipment. Compared with traditional rigid assembly lines, it has the following advantages:

Modular design: easy to quickly change workstations and expand functions;

Strong mixed-line production capacity: can support simultaneous or rapid switching of multiple models of products;

Intelligent scheduling system: improve the automation level of the entire line;

Save labor costs: greatly reduce the number of operators and training costs;

Data visualization and traceability: facilitate quality monitoring and process optimization.

3. Typical application scenarios of flexible assembly lines in home appliance manufacturing

Air conditioning manufacturing: In the production process of air conditioners, from compressors, fans, electronic control systems to shell assembly, there are many components and complex processes. The flexible assembly line can realize the co-line assembly of air conditioners of multiple specifications through intelligent picking system + robot integration, which improves assembly efficiency and consistency.

Washing machine assembly line: Washing machines usually involve the precise assembly of multiple modules such as drums, motors, water pumps, and electric control boxes. By introducing flexible assembly units, multiple options such as drum capacity and shell color can be switched on demand to achieve true "flexible customization".

Refrigerator assembly system: Refrigerator assembly involves a large number of welding, cold injection, sealing and other processes. The flexible assembly line uses modular workstations to achieve seamless assembly of refrigerators with different numbers of doors, refrigeration methods, and capacities, thereby improving flexible manufacturing efficiency.

Flexible production line for small household appliances: Small household appliances such as rice cookers, induction cookers, and vacuum cleaners have faster update and iteration frequencies, smaller volumes, but more parts. The flexible assembly line is combined with fast-changing fixtures and flexible conveying systems to achieve high-frequency product replacement and rapid delivery.

4. The core value of flexible assembly lines

Realize multi-model co-production: Flexible assembly lines solve the pain point of "one line only produces one model" and maximize the utilization of production lines. For example, a mixed line solution designed by a flexible assembly line manufacturer for customers can support 3 models and more than 20 specifications of vacuum cleaners to be automatically assembled on the same line.

Improve production efficiency and product consistency: Compared with manual operation, the process parameter standards in the automated flexible line are unified, the error rate is lower, and the quality is more stable.

Save manpower and reduce operating costs: By introducing robot workstations, AGV handling, and automatic detection systems, a flexible production line can reduce more than 40% of manual operation procedures, effectively alleviating the problem of labor shortage.

Strengthen digital manufacturing capabilities: The flexible assembly line integrates MES system and quality traceability system, which can realize the whole process tracking from raw materials to finished products, helping enterprises move towards smart factories.

5. How to choose a suitable flexible assembly line manufacturer?

Choosing a high-quality flexible assembly line solution provider is the key to ensuring the success of the project. The following are some points to pay attention to when selecting a manufacturer:

Industry experience and case accumulation: It is preferred to select manufacturers with a lot of delivery experience in the home appliance industry, familiar with the assembly process of refrigerators, washing machines, air conditioners, small appliances, etc., and can customize adaptation solutions.

Technical team strength: Whether it has multidisciplinary technical capabilities such as electrical automation, industrial vision, PLC programming, and system integration is an important indicator to measure the manufacturer's delivery capabilities.

Independent core modules and software and hardware matching: For example, whether it has independently developed flexible conveying systems, robot fixtures, production line control software, etc., can greatly improve compatibility and convenience for later maintenance.

After-sales service and delivery capabilities: including installation and commissioning cycle, maintenance response speed, accessories supply guarantee, etc., are the core factors to measure the long-term value of partners.

With the continuous upgrading of consumer demand for diversified and personalized home appliance products, the application of flexible assembly lines in the home appliance manufacturing industry will become the core means of improving quality and efficiency in the industry. It not only improves production efficiency, but also provides a solid foundation for enterprises to achieve intelligent manufacturing. For home appliance manufacturers who are in the critical period of transformation and upgrading, choosing the right flexible assembly line manufacturer and deploying cost-effective flexible assembly line solutions will determine the degree of leading the company in future competition.

If you are a home appliance manufacturer facing challenges such as product diversification, frequent production line changes, and rising labor costs, flexible assembly lines will be an ideal choice for realizing intelligent manufacturing transformation. We focus on providing efficient and customized flexible assembly line solutions for the home appliance industry to help improve production efficiency and market response speed. Please feel free to contact us for professional consultation and one-to-one solution customization services.

http://www.dapkon.ai

Shanghai Dapkon Technology Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.