- This topic is empty.

-

AuthorPosts

-

2025-07-21 at 2:06 pm #10115

In the fast-evolving landscape of chemical processing and laboratory-scale manufacturing, flexibility, efficiency, and reliability are key. Whether in R&D labs, pilot plants, or small-batch production environments, having mixing systems that are both high-performing and mobile can dramatically improve productivity and scalability. This is where skid-mounted stirring kettle units have emerged as an essential solution.

What Is a Skid-Mounted Stirring Kettle Unit?

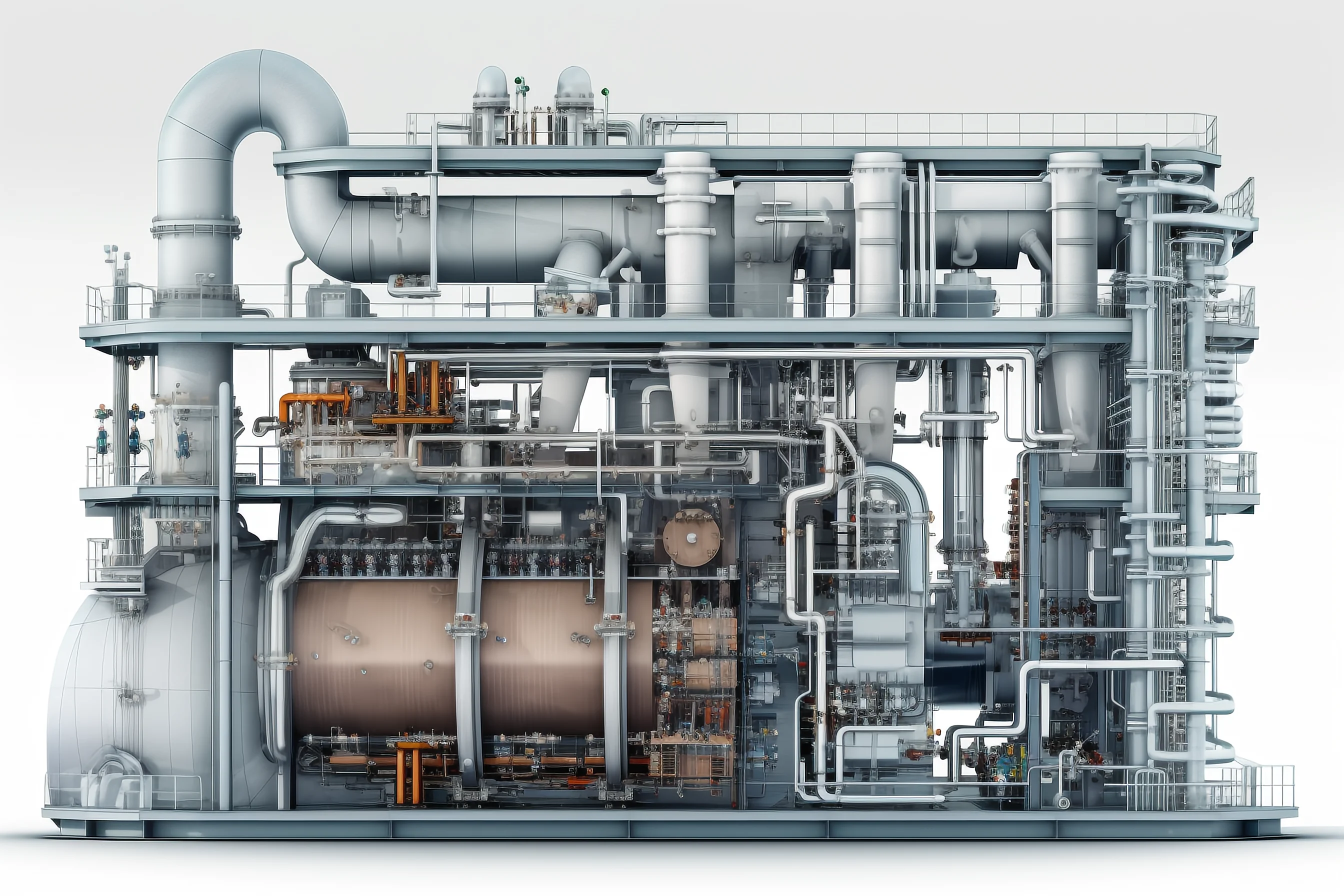

A skid-mounted stirring kettle unit is a modular, self-contained mixing system that includes a reaction or mixing vessel (the kettle), agitators, control systems, pumps, and other auxiliary components—all mounted on a compact steel skid or frame. These units are fully assembled, tested, and delivered ready for quick installation and integration into a facility.

These systems are widely used in sectors such as chemical engineering, pharmaceuticals, materials research, and fine chemical production for batch processing, reactions, emulsifications, and other critical operations.

Chem-Unit: Leading Innovation in Modular Process Systems

As a pioneer in modular chemical equipment solutions, Chem-Unit has earned a reputation for excellence in the design, engineering, and manufacturing of skid-mounted test rigs, pilot-scale systems, and production platforms. Their stirring kettle units represent the intersection of intelligent engineering and practical versatility—designed for real-world industrial challenges.

Chem-Unit’s solutions are used by research institutes, specialty chemical manufacturers, and new materials developers seeking compact, customizable, and scalable processing equipment.

Key Advantages of Skid-Mounted Stirring Kettle Units

1. Enhanced Mixing Efficiency

Efficiency is everything in a controlled reaction or mixing process. Skid-mounted units provide:

High-precision agitation systems, including variable-speed drives, impeller customization, and multi-stage mixing configurations.

Uniform heat transfer, often featuring integrated heating/cooling jackets or coils for thermal control.

Automated process monitoring, including temperature, pressure, and viscosity sensors for real-time adjustments.

These features enable faster, more consistent reactions and higher yields, particularly in sensitive or multi-phase processes.

2. Unmatched Portability and Flexibility

Skid-mounted designs allow for:

Easy relocation within a facility or between departments—ideal for multi-phase R&D or batch testing.

Plug-and-play setup, significantly reducing installation time and infrastructure modifications.

Modular integration, enabling upgrades or combination with additional systems like filtration units, condensers, or robotic samplers.

For companies or labs managing limited space and changing production needs, these systems provide mobility without compromising performance.

3. Compact Footprint and Space Optimization

Traditional mixing systems often require fixed piping, permanent foundations, and extensive utility connections. Skid-mounted systems from Chem-Unit come pre-assembled with:

Optimized piping layout

Minimal wiring

Integrated control panels

This streamlined design makes them ideal for urban laboratories, pilot plants, or mobile processing units where space is at a premium.

4. Fast Commissioning and Reduced Downtime

One of the most compelling reasons to adopt a skid-mounted stirring kettle system is the speed of deployment:

Factory-assembled and tested before delivery

Minimal on-site assembly required

Ready for operation shortly after arrival

This reduces the typical installation and commissioning time from weeks to a matter of days, enabling faster project turnaround and return on investment.

5. High Level of Customization

Chem-Unit offers extensive customization options, including:

Vessel size and shape

Agitator type (anchor, turbine, propeller, etc.)

Material construction ( Hastelloy, glass-lined steel)

Control interfaces (manual, PLC, SCADA)

This adaptability ensures the equipment meets the specific needs of each process, whether it involves high-viscosity fluids, volatile compounds, or sensitive temperature requirements.

Applications Across Industries

Skid-mounted stirring kettles are widely used in:

Chemical R&D and Pilot Trials: Ideal for experimental design and scale-up validation.

Pharmaceutical Processing: Supports GMP-compliant small-batch formulations and synthesis.

Specialty Chemicals: Enables controlled production of adhesives, polymers, or emulsions.

Materials Science: Used for nanoparticle synthesis, coatings, and composite preparation.

Chem-Unit’s Skid-Mounted Solutions: Built for the Future

With a commitment to innovation, Chem-Unit designs its skid-mounted units to meet not just today’s technical requirements, but also tomorrow’s scaling and automation demands. Their offerings can be integrated with:

Automated sampling robots

Data acquisition systems

Remote control and cloud-based monitoring

Whether you're building a pilot plant or modernizing your lab’s mixing capabilities, Chem-Unit provides the expertise and equipment to elevate your process.

Conclusion

Skid-mounted stirring kettle units are reshaping the way industries approach mixing, offering a smart combination of efficiency, portability, and customization. With companies like Chem-Unit leading the way in modular chemical equipment, engineers and scientists can now access advanced, plug-and-play solutions that boost productivity and enable smarter experimentation and production.

If your organization is looking to streamline its process development or scale up production with maximum agility, Chem-Unit’s skid-mounted systems are a powerful and future-ready choice.

Skid-Mounted Unit Series – Integrated, Modular & Easy-to-Deploy Solutions

en.chem-unit.com

Shanghai Chem-Unit Technologies Co. Ltd -

AuthorPosts

- You must be logged in to reply to this topic.